A Brief History of Metal Clay

In the early 1990s, Japan’s Mitsubishi Materials Corporation redesigned the manufacturing facilities they were using to refine gold for use in the microchips they produced. A while later, Dr. Masaki Morikawa, a metallurgist and the director of the new facility was inspired to create a type of modeling clay from the precious scrap left over from the manufacturing process1. His experiments led to what we now know as the brand Precious Metal Clay (PMC®).

Originally conceived as a jewelry making craft medium, the first experiments were made with 24k gold, and then continued with .999 fine silver (the later version of gold added fine silver for strength to create a 22k gold metal clay). In fact, the first objects were golden, ceremonial teacups2, which unfortunately no longer exist.

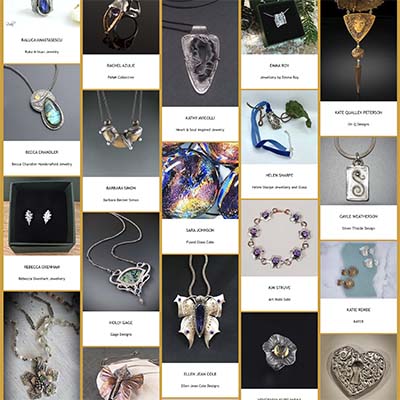

What is it possible to achieve with metal clay is endless

Lora Hart, Three Bottles

Around this same time, scientists working for Aida Chemical Industries developed a similar material now known as Art Clay™ Silver (ACS). Patents for both brands were granted in 1994, debuting in Japan just months apart.

In 1995 Mitsubishi Materials Corporation presented an experimental PMC® workshop at Haystack Mountain School of Crafts in Deer Isle, Maine led by metalsmith Tim McCreight and later that same year began a partnership with distributor Rio Grande®3.

Focusing on the European market, Art Clay™ Silver didn’t appear in the US until 1997 after opening its first distributorship in Torrance, California.

Base metal clays began to hit the market around 2008 after the Japanese patents ran out. Various artists had been experimenting with making copper clay with some limited success, but it wasn’t until Bill Struve discovered that the secret to sintering base metal clays lay in using an oxygen-deprived atmosphere that firing became more consistent. Bill created and released Metal Adventures brand clays, followed soon after by Hadar Jacobson’s eponymous Hadar’s Clay™.

Sterling silver (.925), an alloy of 92.5% fine silver and 7.5% copper, was introduced in 20124; but since .925 has to be fired in carbon in the kiln (a process that some consider messy and time consuming), ‘enriched’ forms of sterling were created which could easily be fired in an open kiln. Stronger than pure .999 silver, the copper enriched blends of .950 sterling, and .960 sterling came on the market in 2016.

Now, a little more than twenty years after the first metal clays became commercially available, there are over 21 manufacturers around the world making 120 different metal clay types of various alloys and working properties.

With the development of so many unique alloys, colors, working properties, and other options available to a creative artist – we can acknowledge that metal clay has come a long way, baby! Instead of imagining what could be made with it, it might be easier to think of what and how it couldn’t be used by future artisans.

1 Tim McCreight, PMC Decade

2 Darnell Burk, PMC Decade

3 Tim McCreight, PMC Decade

4 Hattie Sanderson, Contemporary Metal Clay Rings

Metal clay has come a long way in the last 20 years

Anna Mazon, Midsummer Night