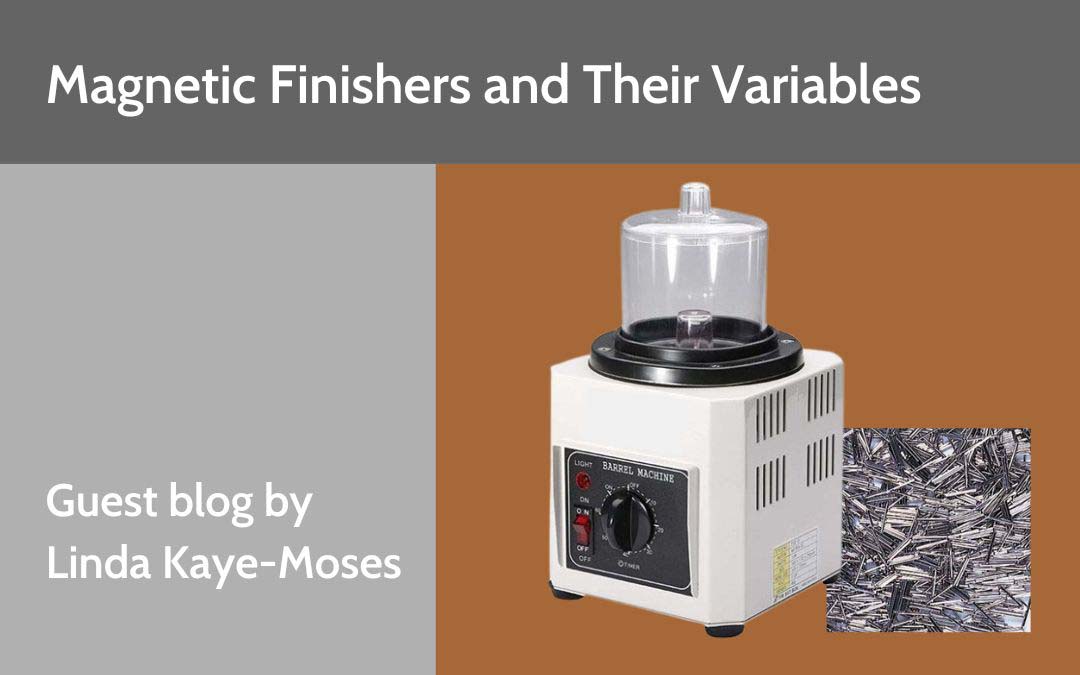

I always use a magnetic finisher to burnish my pieces right out of the kiln, whether I’m planning to simply patinate them or enamel. This machine creates a surface that works for both processes. When I taught “Grooving on Metal Clay & Enamels” at The Enamelist Society Alchemy6 Conference, one of my students mentioned that she had a magnetic finisher, but was unable to produce a bright and burnished finish on her pieces using her machine. Even though this type of machine seems uncomplicated to use, there are a number of variables that can affect the results. We discussed the variables that might be affecting her results, and after I returned home, I created this summary for my students.

What is a magnetic finisher?

A magnetic finisher (or mag finisher) is simply a magnetic tumbler spinning a lot of magnets. The parts are:

- power source

- magnets in a sealed compartment

- stainless steel pins/pins

- a bowl

- a burnishing liquid

The concept is simple: magnet(s) go around and around, pulling stainless steel shots/pins in a bowl set above them as they go. Your metal objects are in the bowl in a lubricating (burnishing liquid) solution; as the pins move rapidly over and around your metal objects, they polish your pieces. The finishing components are: the solution, the lubricant, the pins – period.

All The Other Variables

There are a number of other variables which affect the finishing quality of your magnetic tumbler:

- water quality and quantity

- magnet quality/strength

- type, quantity and care of pins

- type of burnishing liquid

- duration

- material of bowl

- power that rotates the magnets.

1. The Water

Water Quality

One variable is your water. Is it municipal or well water? If it’s well water, there might be minerals in it that can interfere with your finish. Try using distilled water.

How much water?

Add water about 1/3-1/2 way up the sides of the bowl. Too much water makes the process less efficient.

2. Quality Of The Magnets And Machine

THIS IS A MAJOR VARIABLE TO CONSIDER. Not all mag finishers are capable of doing the job; that is, the quality of these machines can vary. Stick with machines sold by trusted, reputable suppliers.

3. The Pins

3. The Pins

The small bits of steel that do the job for finishing in tumblers have traditionally been termed ‘shot.’ This is because those that were originally used in rotary tumblers were similar to the shot used in, yup, shotguns. The terminology stuck. The shot used in mag finishers is different. It’s called “pins” and should look like small lengths of thin steel wire/rod. Mine are about 1/4” in length and about 22 gauge in diameter. These pins have blunt ends, not sharp ends.

What Do The Pins Do?

The pins burnish the metals objects in the bowl.

Quantity of Pins?

Less than 1/2 to 1 cup of pins works best, depending on the size of the bowl. A better way to describe this quantity would be to say: add enough pins to the bowl to cover the floor of the bowl about 1/8 inch thick. Adjust by adding more, if needed.

Using too many pins can interfere with the efficiency of the process. If the bowl has too many pins and/or solution, the power source for rotating the magnets may not be strong enough to handle the weight, and that will make it work less efficiently, or not at all.

Care and Treatment of Pins

Mag finishers use stainless steel pins. If your pin rusts, it’s not stainless. It must be dried after every use. That’s just not convenient. And, if it rusts, it can discolor your objects.

Stainless steel pins can be left in the bowl under water. I’ve left mine in water for months of use, even after they become darker and darker (and a little slimy). They still produce a burnished finish.

If the pins are really dirty, and that can take months of use, that can interfere with getting a bright finish, and may in fact darken the surface of your pieces. Clean the pins with a commercially available pin cleaner (although, for this task, I have used a mild dishwashing detergent), by adding it to water in the bowl and running the machine for about 10 minutes. Rinse completely afterwards.

4. The Burnishing Liquid

Burnishing liquid is a misnomer. The pins do the burnishing. The burnishing liquid lubricates and makes the water slippery, and allows the pins to slide around and over the pieces of metal objects being burnished, without imparting a layer of steel on those objects, while brightening the surface of the objects.

How Much Burnishing Liquid?

Add only 2-3 drops of burnishing liquid to the water (a maximum 5 drops) to start. Watch for a layer of ‘soapy foam’ and add no more. Use a commercially available burnishing liquid designed for machine finishing (like Rio Grande’s Sunsheen or similar product). Do Not USE dishwashing liquid. It doesn’t do the job well, if at all.

5. Duration Or How Long To Run The Machine

Run the machine 5-10 minutes. Check the result.

6. The Bowl

If your pieces are not getting burnished sufficiently or the surface seems dark, the material of the bowl might be the culprit. It might be outgassing into the solution. I haven’t experienced this, but it’s a possible variable if your objects are simply not being burnished and you’ve eliminated all other variables.

Substitute a lighter weight plastic bowl. Something well used, like a round freezer or other food storage bowl, about the same size. Doesn’t really need a cover, though that keeps the noise level down.

7. The Power

Whatever activates the rotation of the magnets needs to be powerful enough to do that, even with a fully loaded bowl (water, pins, objects) for the length of time required to burnish the objects. Some off-brand machines, usually less expensive, may not have the power to do this well, and should be avoided. This is another reason to purchase a mag finisher from a trusted and reputable supplier.

Guest blog by Linda Kaye-Moses

Guest blog by Linda Kaye-Moses

Read Linda’s entire fun and photo-filled recap of her teaching experience at The Enamelist Society Alchemy6 Conference here. Don’t miss the link she includes to a video of her presentation on Enamelling on Metal Clay 2022.

Linda is a well-known jewelry artist who makes “audacious, unruly jewelry,” working in metal clay, enamels, and other artistic mediums.

Her work has been featured in juried shows, exhibits and in galleries across the U.S., and she has served as a juror for many exhibits and shows, including the Saul Bell Design Awards.

You can find Linda online at www.lindakayemoses.com.

3. The Pins

3. The Pins Guest blog by Linda Kaye-Moses

Guest blog by Linda Kaye-Moses