Cutting and Drilling

Twist drills are made in a few different metals and a couple of mandrel configurations. The size of the mandrel most often corresponds to the size of the flutes of the bit. This means that a very narrow or large drill will not fit in a quick-change motor tool handpiece or in most micromotors, so you’d need to buy a pin vise adapter to mount them in any handpiece other than the #30. But some manufacturers make drills with a 3/32-inch (approx. 2.38mm) mandrel, no matter the drill size. They’re a little more expensive, but the convenience might be worth it.

Diamond drill bits – tiny, industrial diamonds are either simply mounted to the surface or sintered into the body of diamond drills. The less expensive surface version will eventually wear down to the original tool metal, but the sintered ones have diamond through and through, so as they wear down, new diamond particles are being revealed. More expensive, but you’ll get much more use out of them.

Diamond core or twist drill bits are often used for adapting tools, drilling holes in stone or glass, and reaming pearls. Please note that diamond drills’ bit size is not as accurate as metal drill bits due to the diamond coating.

Metal drill bits – there are so many different kinds of drill bits that it can get really confusing when looking through a catalog. Tungsten, Vanadium, Carbide steel, the list goes on. For our purposes – whether using them on dry clay, sintered metal, or milled metal, you want to find High-Speed Steel (HSS) drill bits. ‘High-speed steel’ is not the same as just ‘high-speed’– so read the description carefully before you buy a set of drills.

Drills will not fit into a wire gauge because the flutes get caught on the slots’ edges, so you might also want to invest in a drill gauge. Look online to find a comparison chart of drill sizes versus metal gauge or mm. For instance, 1mm = 4 cards unfired metal clay = 18-gauge sheet or wire and is closest to a #60 drill bit.

Drills, stone setting burs, and wire rounding cup burs are all metal. Both the business end and the shaft have been machined out of a single wire.

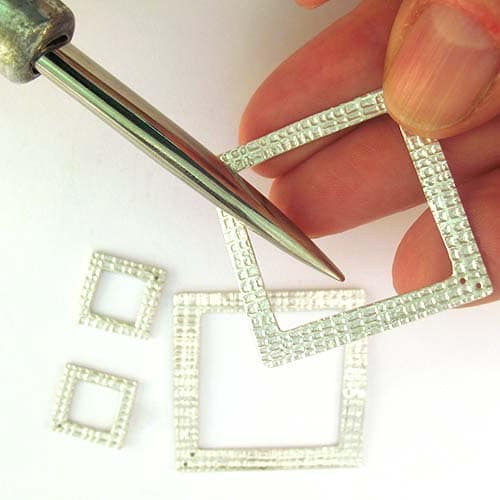

Use a drill to create a hole for a jump ring or just drill holes as an added decoration. To start a hole in either dry metal clay, sintered metal clay, or milled metal, first put a divot into the workpiece. The drill point now has somewhere to rest as it starts to revolve; otherwise, centrifugal force will spin the drill all over the workpiece and scratch the surface instead of drilling a hole.